Oil Mist & Oil Smoke Applications

Select your application below to get started:

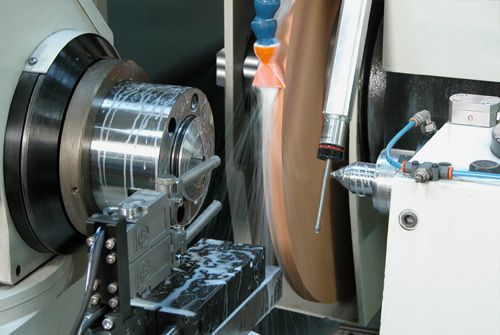

Machining

Almost every machine process generates oil mist, oil smoke, or a combination of both. When the friction and speed of a machining tool and the coolant used for protection merge, oil mist and smoke are produced creating a negative effect on employee health and production equipment if proper filtration is not in place.

Read More

Cold Heading/Forming

Cold heading, also known as cold forming, can be utilized to remove small amounts of metal and to reduce and expand the length and diameter of coiled wire. Oil lubrication is used to prevent die wearing in cold heading processes. When the lubricant is applied, heat vaporizes resulting in oil smoke and oil mist.

Read More

Grinding

CNC grinding utilizes machines that have a rotating grinding wheel to remove material from a workpiece through abrasion. CNC grinding abrasion and high spindle speeds produce great levels of heat. When this heat is combined with the high-pressure coolant used to chill a workpiece, large concentrations of oil smoke and mist are emitted.

Read More

Heat Treatment

Metal heat treatment implements extreme temperatures to achieve the hardening or softening of a material. During heat treating, metal material is heated, soaked, and promptly chilled, transmitting oil mist and smoke. Heat treating may consist of both oil mist and smoke, with oil smoke being a larger concern due to the size/volume of particles.

Read More

Die Casting

Die casting is a type of metal casting method that uses high-pressure to force molten metal into a mold cavity to produce a specific shape. Die casting involves high-heat temperatures, rapid friction, and high-pressure coolants, when combined, oil smoke, and oil mist are produced at submicron sizes and in heavy concentrations.

Read More

Forging Press

Cold, warm, and hot forging are determined based on if the metal temperature is above or below the recrystallization temperature. When metals are forged, techniques such as rolling, pressing, or forming may be used to develop specific shapes. The friction of these techniques produce oil smoke which requires immediate filtration.

Read More

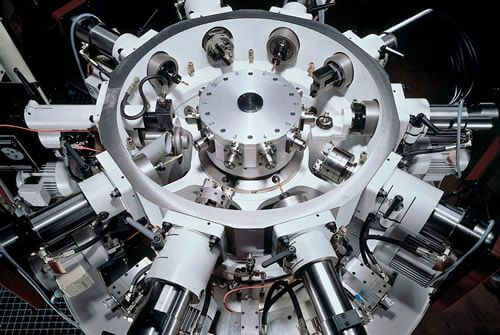

Hydromat Machining

Hydromat rotary transfer machines can form oil mist, oil smoke or a variation of both. Handling machinery and products coated in a film of oil and working in an environment with slippery floors and work surfaces not only slows down production but can also severely affect the health of machine operators.

Read More