CNC Grinding Oil Smoke/Mist Collection

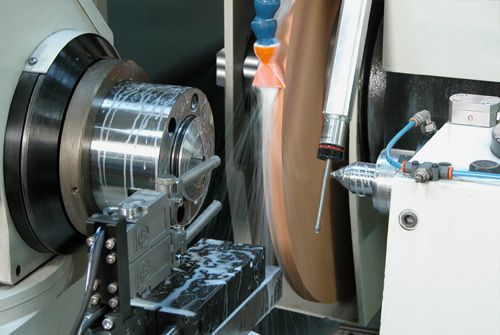

CNC grinding is a computerized numerical control process that utilizes machines with a rotating grinding wheel to remove material from a workpiece through abrasion.

Each grain on the surface of a CNC grinding machine's wheel cuts small chips from a workpiece, this method is called shear deformation and is used to achieve high surface quality and precise shape and dimension. Because of the precision in this process, CNC grinding is often used to produce parts for automotive, medical, and aerospace industries, among more.

The abrasion and high spindle speeds in CNC grinding produce great levels of heat. When this heat is combined with the high-pressure coolant used to chill a workpiece, large concentrations of oil smoke and oil mist are emitted.

To ensure a clean air and safe work facility, it is imperative that CNC grinding environments are equipped with oil smoke and mist collectors for immediate filtration and removal of harmful contamination. With an efficiency of 99.95% @ 0,3 µm, ScandMist is the best-proven technology available. Improve production efficiency, establish a safer workplace, and reduce environmental impact with ScandMist.

CNC Grinding Methods

|

|