Why Choose ScandMist

ScandMist vs. Electrostatic Precipitators & Centrifugal Techniques

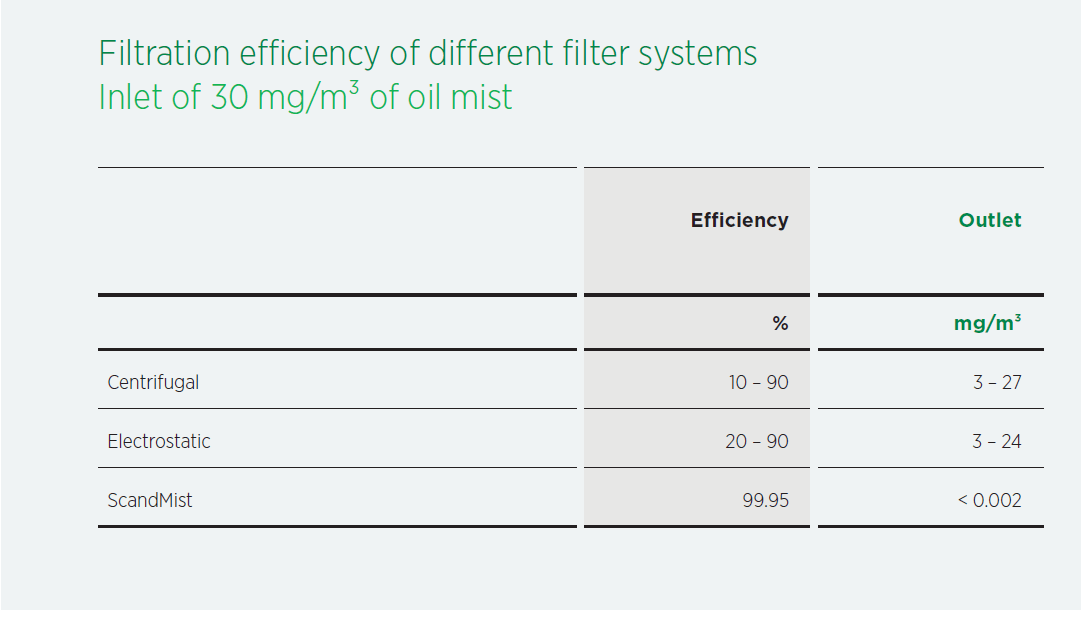

While there are a variety of technologies available to combat oil mist and smoke, it's important to know that the smaller particulate is, the less efficient electrostatic precipitators and centrifugal techniques are.

For example, in CNC machining applications, the most common and harmful contaminant is PM1. Electrostatic precipitators and centrifugal techniques can work well for relatively large PM10 and at times PM2.5 particles, however, their performance against smaller particulate is inadequate.

The truth is, submicron PM1 particles are too small for electrostatic preciputators and centrifugual techniques to capture and pass through effectively.

HEPA filtration may be used after an electrostatic or centrifugal filtration process, but because the initial stage is unable to remove large quantities of PM1, this submicron particulate quickly clogs the fine media of HEPA filters resulting in frequent and costly changes.

Because ScandMist implements coalescers in the first two filtration states, our mist collectors have the ability to gather and coalesce submicron particles into larger droplets which drain to the bottom of the machine or into a separate oil sump for reuse.

This process provides high efficiency, protects the final HEPA filters, and prevents each stage from becoming clogged with fine particulate which results in longer filter life and prolonged performance.