Hydromat Machining Oil Mist/Smoke Collection

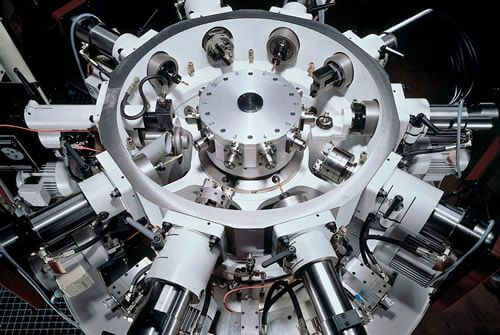

Hydromat machining involves versatile, modular, rotary transfer machines (Hydromat, Tornos, and BTB) that work well across a diverse range of machining operations and feature a rigidly mounted horizontal and vertical tool spindle set-up to provide high-quality precision in the following applications:

|

|

|

During production, coolants are mixed with concentrated cutting fluid creating emulsion which is used for lubricating, cooling or chip removal. Emulsion is the cause of oil mist and oil smoke development.

Because Hydromats feature a modular system that is made up of horizontal and vertical tool spindles rigidly mounted around a precision cast iron ring, they are able to provide flexibility and eliminate the need for secondary machines and/or processes.

Hydromat rotary transfer machines can form oil mist, oil smoke or a variation of both. Handling machinery and products coated in a film of oil and working in an environment with slippery floors and work surfaces not only slows down production but can also severely affect the health of machine operators.

Repeated exposure to oil mist and oil smoke in Hydromat Machining facilities can result in a variety of health effects that range depending on short to long-term exposure:

|

|