Oil Mist & Particulate Matter

The Threat is Microscopic

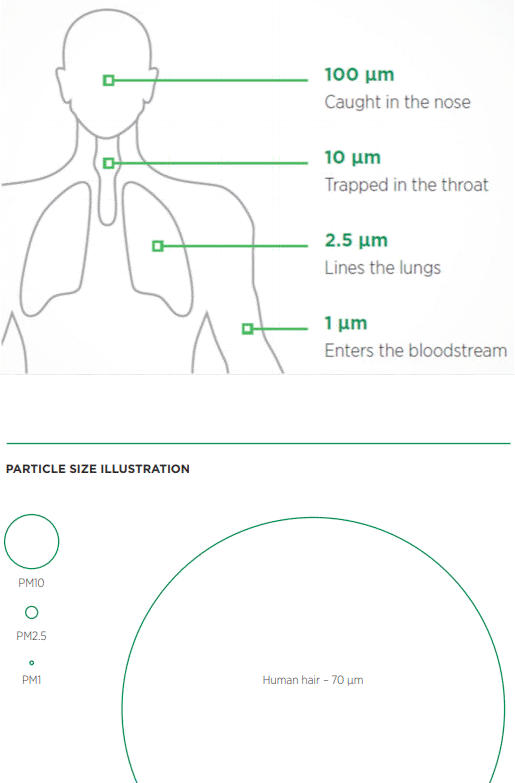

Particulate matter (PM) is microscopic solid and/or liquid airborne contamination that can be man-made or occur naturally. Large amount of PM concentrations are commonly found in industrial working environments which is why it’s critical to understand the effects that PM can have on employees in your workplace.

Particulate Matter - Harmful to Every Body

Humans can stop particles larger than 10qm from entering the body. However, there are smaller particulates that pass the defense system. PM1 passes through the walls of the lungs and enters the blood stream resulting in severe organ damage.

1 out of 9 deaths are linked to air pollution and particulate matter is a large contributor to that.