MQL Emissions Control

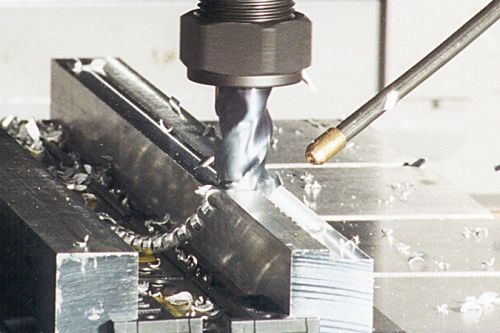

MQL, or minimum quantity lubricant, cools machining processes by using compressed air and reducing friction by applying atomized lubricant spray directly to the surfaces of cutting tools and workpieces instead of implementing traditional flood coolants.

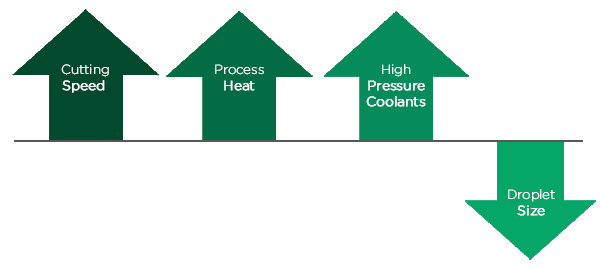

MQL minimizes environmental impact by reducing fluid usage and eliminates the need for coolant treatment and removal. The emissions from minimal quantity lubrication cannot be exhausted with a mist or dust collector because they are not wet or dry. MQL emissions are considered semi-dry and medium wet.

• Medium wet applications are determined by a combo of drainable droplets and non-self-drainable particles.

• Semi-dry applications are defined by a certain volume of wet particulate mixed with sticky semi-fluid and non-self-drainable particles.

Image Resource: Abrasive Innovations